Talking about the influence of processing aids on the cold r

欄目:Industry News 發(fā)布時間:2021-06-03 15:19

Medical PVC pellets are often used in various injection-molded medical products, such as oxygen masks, medical goggles, external liquid containers, etc. If such products are used in winter or low temperatu...

Medical PVC pellets are often used in various injection-molded medical products, such as oxygen masks, medical goggles, external liquid containers, etc. If such products are used in winter or low temperature areas, if they encounter low temperatures, whether they will be brittle , Impact resistance is severely reduced, etc., to a large extent depends on the level of use of additives by PVC pellet producers. This article will talk about the indirect influence of processing additives on the cold resistance of medical PVC pellets.

For enhancing the cold resistance of medical PVC pellets, Jiahong Plastics adopts blending modification. After blending, the modified PVC pellet product can change the physical and mechanical properties and processing properties. Cold-resistant polyvinyl chloride resin is difficult to process due to its large molecular weight, so polyolefin modifiers are added to the formulation to improve processing Performance, viscosity, elasticity, etc. However, the amount of modifier has a certain impact on cold resistance. The increase in the amount of modifier will increase the embrittlement temperature. But the change is small within a certain range.

There is a compatibility problem with the blending of two polymers, and most polymers do not have thermodynamic compatibility. Only when the blend is homogeneous on the macroscopic and heterogeneous on the microscopic and sub-microscopic levels. Good physical properties. But when the amount of modifier is too much, phase separation will occur, that is, the macroscopically heterogeneous phase, which has a greater impact on the physical properties. Therefore, the amount of modifier should be controlled when designing the formula. The increase in the amount of plasticizer helps to improve the cold resistance. A large amount of small molecule plasticizers penetrate into the high molecular weight resin to improve the processing performance and give the product good cold resistance.

The formula of cold-resistant PVC pellets combines many factors, and the embrittlement temperature is 15℃ lower than that of ordinary pellets; cold-resistant PVC pellets are suitable for the field of hand-medical t-shirt equipment. The new generation of cold-resistant plastics produced can improve the low temperature of ordinary medical plastics. Rigidity and brittleness lead to centrifugal damage and low-temperature storage damage; and the hand feels soft, elastic, and the flipped product is beautiful.

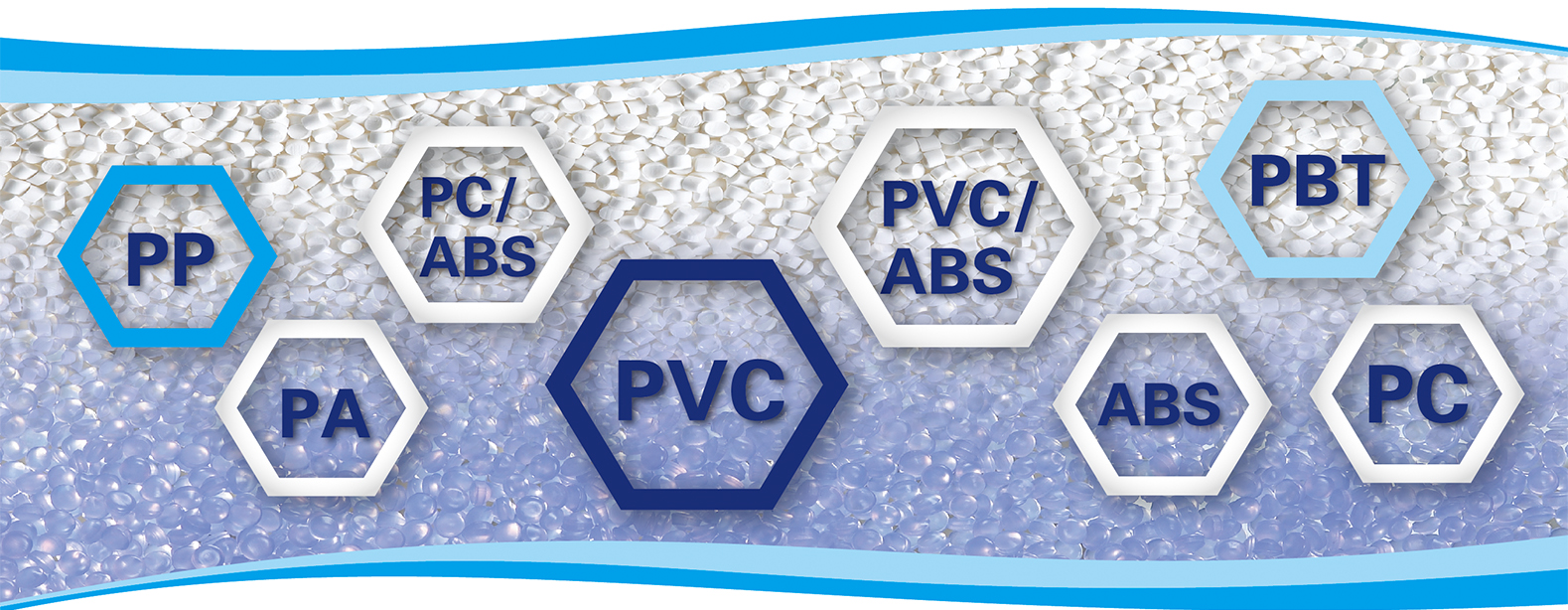

Wuxi Jiahong Plastic Technology Co., Ltd. can process various filled, flame-retardant, reinforced modified ABS, PS, PC, PC/ABS, polypropylene, PA and other engineering plastic particles according to customer requirements; various car door panels, bumpers, dashboards , Engine cover, car lights and other automotive special materials.

Wuxi Jiahong Plastic Technology Co., Ltd. has nearly 30 years of experience in R&D and pelletizing production of PVC pellets, and experience in R&D and production of modified engineering plastics. The professional technical service team can provide customers with one-stop modified plastic system solutions. If you want to know more about the product, please log in to our official website: www.r9390.cn, consult online customer service or call the hotline. Landline: 0510-68755207 Mobile: 15190220696, we will serve you wholeheartedly.

(Disclaimer: All the tutorials and resources included in this site are from the Internet, and their copyright belongs to the original author and his website. Although this site strives to preserve the original copyright information, it may not be able to be determined due to many reasons. The true source, please forgive the original author! If you have any objections to the attribution of the tutorials and resources on this site, please notify the editor immediately. The situation is true and we will delete it as soon as possible.)